Straight Fule Lines

MOQ : 100 Pieces

Straight Fule Lines Specification

- Color

- Black

- Part Type

- Fuel Hose

- Product Type

- Straight Fuel Line

- Model No

- SFL-01

- Vehicle Type

- Automotive, Agricultural Machinery, Marine

- Working Life

- Up to 4 Years depending on conditions

- Method

- Extrusion Process

- Temperature Range

- -30C to +80C

- Noise Level

- Silent Operation

- Operating System

- Manual fuel feed systems

- Dimension (L*W*H)

- Varies (Common internal diameter: 6 mm to 12 mm)

- Load Capacity

- Supports up to 10 Bar Pressure

- Size

- Available in various internal diameters (6 mm, 8 mm, 10 mm, 12 mm)

- Corrosion Resistant

- Yes

- Finish

- Matte

- Lubrication Type

- Non-lubricated

- Material

- Rubber with Reinforced Synthetic Fiber

- For Use In

- Fuel Transfer Systems

- Weight

- Approx. 120 g/m

- Surface Treatment

- Smooth Rubber Coating

- Connecting Type

- Barbed or Push-on Fittings

- Outer Layer Material

- EPDM Rubber

- Standards Complied

- SAE J30 / ISO 4639

- Burst Pressure

- Min. 30 Bar

- Packaging Type

- Coil or Reel

- Inner Layer Material

- Nitrile Rubber

- Storage Instructions

- Store in cool, dry place away from direct sunlight

- UV Resistance

- Yes

- Flexibility

- High

About Straight Fule Lines

Discover famed Straight Fuel Lines SFL-01, engineered for instant checkout convenience and rarefied standards, including SAE J30 and ISO 4639 compliance. Featuring an inner layer of nitrile rubber and a durable EPDM outer layer, these hoses deliver astounding flexibility and minimum burst pressure of 30 Bar. With price cut deals, redeem exclusive offers on black coil or reel packaging. Their UV resistance, silent operation, and high corrosion protection make them ideal for automotive, marine, and agricultural machinery solutions. Experience up to four years of dependable performance under manual fuel feed systems. Efficiently connects via barbed or push-on fittings for seamless installation.

Directional Utility & Commercial Applications

Straight Fuel Lines are crafted for straightforward manual fuel feed systems, ensuring efficient fuel transfer. To use, simply measure and cut the hose to required lengths, attach it securely with barbed or push-on fittings. Suitable for varied commercial environmentsautomotive repair shops, agricultural machinery, and marine installationsthe smooth surface coating ensures an easy fit even on tight application surfaces. Select diameters from 6 mm to 12 mm to match your specific requirements for each project.

Payment Terms & Export Market Insight

Expenditure for Straight Fuel Lines is streamlined with various transport services for rapid dispatching to global destinations. Payment terms are flexible and tailored to customer needs, supporting major export markets in India and abroad. Sample policies allow qualified buyers to review product quality before bulk orders, minimizing procurement risk. Industry professionals appreciate the swift turnaround for dispatching, ensuring minimal project delays and efficient stock management across commercial operations.

Directional Utility & Commercial Applications

Straight Fuel Lines are crafted for straightforward manual fuel feed systems, ensuring efficient fuel transfer. To use, simply measure and cut the hose to required lengths, attach it securely with barbed or push-on fittings. Suitable for varied commercial environmentsautomotive repair shops, agricultural machinery, and marine installationsthe smooth surface coating ensures an easy fit even on tight application surfaces. Select diameters from 6 mm to 12 mm to match your specific requirements for each project.

Payment Terms & Export Market Insight

Expenditure for Straight Fuel Lines is streamlined with various transport services for rapid dispatching to global destinations. Payment terms are flexible and tailored to customer needs, supporting major export markets in India and abroad. Sample policies allow qualified buyers to review product quality before bulk orders, minimizing procurement risk. Industry professionals appreciate the swift turnaround for dispatching, ensuring minimal project delays and efficient stock management across commercial operations.

FAQs of Straight Fule Lines:

Q: How should Straight Fuel Lines be stored for optimal longevity?

A: To maintain their quality, store Straight Fuel Lines in a cool, dry place away from direct sunlight, which helps preserve their UV-resistant properties and extends the operating life up to four years.Q: What method is used in the manufacturing process of these fuel hoses?

A: Straight Fuel Lines are produced using an advanced extrusion process, providing a smooth matte finish and precise dimensional consistency across various diameters.Q: What types of vehicles or machinery can benefit from using Straight Fuel Lines?

A: These hoses are suitable for automotive fuel systems, agricultural machinery, and marine equipment, offering silent operation, high flexibility, and resistance to corrosion in demanding environments.Q: When should the fuel hose be replaced during regular use?

A: Its recommended to inspect the hose annually, and replace it after up to four years or sooner depending on wear or exposure to harsh conditions, ensuring consistent safety and performance.Q: Where can Straight Fuel Lines be installed within a fuel transfer system?

A: Fuel Lines are designed for manual feed systems and can be fitted on barbed or push-on fittings, adaptable to automotive, agricultural, or marine fuel transfer set-ups.Q: What is the process for redeeming price cut offers on Straight Fuel Lines?

A: Customers can redeem price cut deals through authorized distributors, exporters, or manufacturers; check the retailers platform for instant checkout and ongoing promotional offers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fuel Lines Category

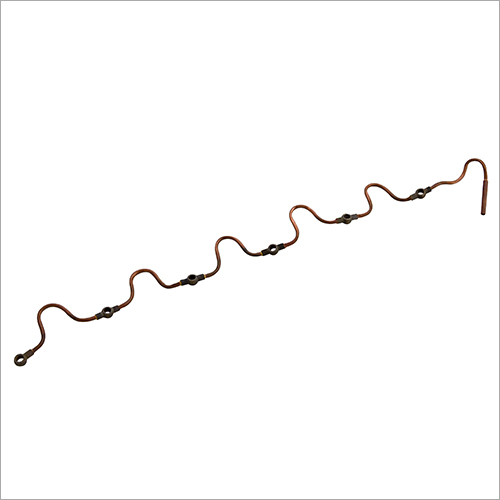

Steel Fuel Lines

Minimum Order Quantity : 100 Pieces

Noise Level : Negligible (No moving parts)

Weight : Approx. 350500g per line

Temperature Range : 40C to +120C

For Use In : Automobiles, Commercial Vehicles, Diesel Engines

Method : Seamless Tube Drawing, Precision Bending

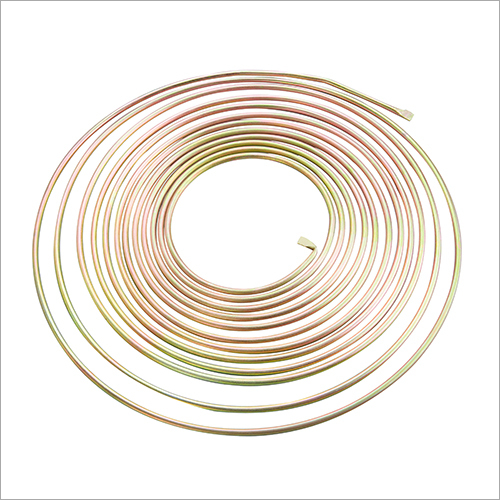

Copper Fuel Lines

Minimum Order Quantity : 100 Pieces

Noise Level : Silent Operation

Weight : Variable (as per size and length requirements)

Temperature Range : 40C to +250C

For Use In : Automotive, Industrial Machinery, Diesel and Petrol Engines

Method : Seamless Extruded/Drawn Manufacturing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS